Prof. Charlotte K. Williams, Dr Diego Resendiz, Mr Edward Shellard, Mr Lukas Wille, Department of Chemistry, University of Oxford

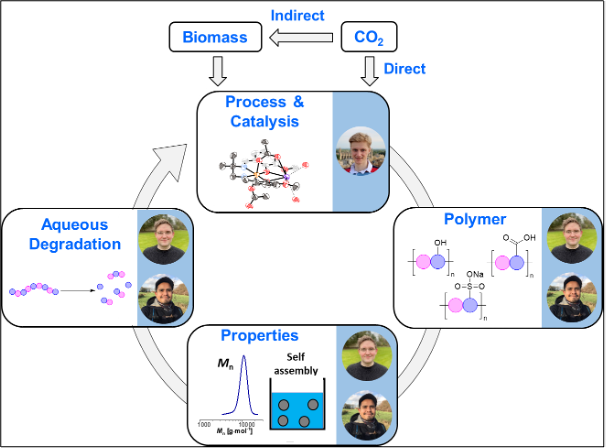

Our team in the prosperity partnership investigate all aspects of the life-cycle of sustainable polymers for home care applications. Polymers are widely used in Unilever’s business providing function and value in areas like laundry, fabric care and cleaning products. We focus on the fundamental science underpinning the design, preparation and properties of polymers used in these formulations. Our approach is holistic considering the raw materials used to make the polymers, how polymers are produced, designing the structures for the properties needed in products through to their complete biodegradation after use.

The polymers are designed to be sourced from renewable resources, like waste biomass and carbon dioxide. Polymers are prepared using efficient (co)polymerizations, in particular we exploit living polymerizations of lactones, cyclic carbonates, anhydrides, carbon dioxide and heterocycles. We focus upon inventing new and better polymerization processes, and catalysts, that will transform bio-derived raw materials into well-defined useful polymers. The prosperity partnership allows us to investigate how best to make polymers showing the most suitable properties for a range of applications. Through catalyst design, we take advantage of very well controlled polymerizations to allow insight and understanding of structure-property relationships. Our polymerizations allow us to control and systematically vary polymer compositions, chain lengths, architectures and morphologies and monitor how these features influence performances. To make the polymers, we use custom-built reactors featuring various spectroscopic probes which allow for monitoring, in real time, of the reagent conversions, polymerization kinetics and product selectivity.

Our team also investigates the characterization of the new polymers using spectroscopy, GPC and a range of thermal-rheological and mechanical testing apparatus. The polymers are applied in aqueous formulations and so materials need to be hydrophilic or amphiphilic, yet fully degradable. We investigate the properties of polymers in aqueous solutions and as self-assembled nanostructures. The polymers feature ‘functional groups’ which are added at precise points along the backbone to deliver better properties in the liquid formulations. After use, these polymer cannot be recycled since they are disposed of as dilute solutions in waste water, this means we need to prepare polymers which can be fully biodegraded to metabolites. In the prosperity partnership, we work collaboratively to accelerate understanding of the degradation mechanisms, rates and products. For example, partnership between our group and scientists at Unilever and in the Cooper research team at the university of Liverpool focusses on accelerating testing protocols and understanding of biodegradation reactions. Key to the success of the prosperity partnership is interdisciplinary collaboration. All our work is closely integrated with the wider team, from the experts working in catalysis and monomer production, to those developing robotic platforms and automated methods to the scientists building theoretical models to better understanding polymer structure-property relationships and, of course, through collaboration with the scientists working at Unilever on product application development.

Recent Papers

(1) Diment, W. T.; Lindeboom, W.; Fiorentini, F.; Deacy, A. C.; Williams, C. K. Synergic Heterodinuclear Catalysts for the Ring-Opening Copolymerization (ROCOP) of Epoxides, Carbon Dioxide, and Anhydrides. Acc. Chem. Res. 2022, 55 (15), 1997-2010. DOI: 10.1021/acs.accounts.2c00197.

(2) Deacy, A. C.; Gregory, G. L.; Sulley, G. S.; Chen, T. T. D.; Williams, C. K. Sequence Control from Mixtures: Switchable Polymerization Catalysis and Future Materials Applications. J. Am. Chem. Soc. 2021, 143 (27), 10021-10040. DOI: 10.1021/jacs.1c03250.